How to choose the most effective PVC Connectors

Are you going to save money by using low-quality PVC connectors and fittings in your plumbing project? It's best not to do it. PVC connector compromises can be disastrous. We attempted to understand the characteristics of effective PVC connectors from the perspective of experienced plumbers and fabricators in this article. With high-quality connectors and fittings, you can't go wrong.

What are the functions of pipe connectors?

Pipe and tube connectors and fittings come in a variety of shapes and sizes, including Collar, Elbow, Gasket, Union, Reducer, Tee, Nipple, and Trap. In a plumbing job, each of these fittings serves a specific purpose. Some of the aren't we all aware of that? Let us take a look.

• Pipe connectors and fittings aid in the adaptation to various shapes and sizes of piping and tubes

• They manipulate the flow of water (or other fluids) through the plumbing system to change its direction and distribution

• In any plumbing project, piping joints and bends must withstand a high-water pressure load; connectors must withstand the pressure and prevent leaks

• Connectors and fittings aid in the installation of pipes in difficult-to-reach areas, such as tight corners and curved planes where straight pipes cannot be used

• Pipe fittings also help to distribute and carry the weight of pipes in a vertical plumbing system to some extent

The quality of PVC connectors

Material quality - Connectors can be made of a variety of PVC materials, such as cPVC and uPVC, each with its own set of strengths, durability, and advantages. Chlorinated polyvinyl chloride (cPVC) fittings can be used with both hot and cold water. Un-plasticised PVC or uPVC pipes and fittings, on the other hand, have a higher tensile and impact strength and thus last longer.

Pressure and temperature bearing capabilities

Better pressure and temperature bearing capacity connectors and fittings increase the overall longevity of plumbing work across seasons.

Low thermal expansion and contraction

PVC connectors should match the thermal expansion and contraction of the attached PVC pipes and tubes. Otherwise, piping work is subjected to unnecessary stress as a result of daily and seasonal temperature fluctuations.

Fast and simple installation

Consistent, dependable pipe connector design and finishing are essential for making installation work easier and less labour-intensive. PVC connectors and fittings with better finishing require less solvent cement, lowering the overall cost of the project.

Low maintenance needs

Your chosen PVC connectors and fittings should not necessitate regular upkeep and maintenance, as this raises the lifetime ownership costs of plumbing work.

Summary

For your plumbing project, consider Polyfab's Sockets, Tees, Elbows, Bushes, Ball Valves, and other PVC connectors and fittings. For quality, durability, and long-term sustainability, they are always the preferred choice of reputable plumbers and fabricators. Contact our sales team to know more.

Our Other Blogs

- PVC Pipes and their importance

- HDPE Pipes Applications & It's Uses

- Are PVC Pipes Safe for the Environment?

- Benefits of PVC Pipes

- How to Cut and Assemble PVC Pipes Easily?

- How to Perform a Pipe Inspection

- How to Select Plumbing Pipes for a Commercial Building?

- What are the Advantages of HDPE Pipe?

- What are the Different Types of PVC Fittings?

- Why to Use HDPE Pipes and fittings?

- How to Maintain and Take Care of Your Plumbing Systems

- Why Should You Choose Polyethylene Pipe (HDPE pipes) for Your Water Utility Project?

- Points To Consider Before Installing Drainage System

- Everything You Should Know About HDPE Piping for Your Water Utility

- HDPE Piping

- HDPE Pipe Joining Methods

- 5 Reasons to use HDPE pipes in Irrigation System

- Benefits of Using PVC Pipes

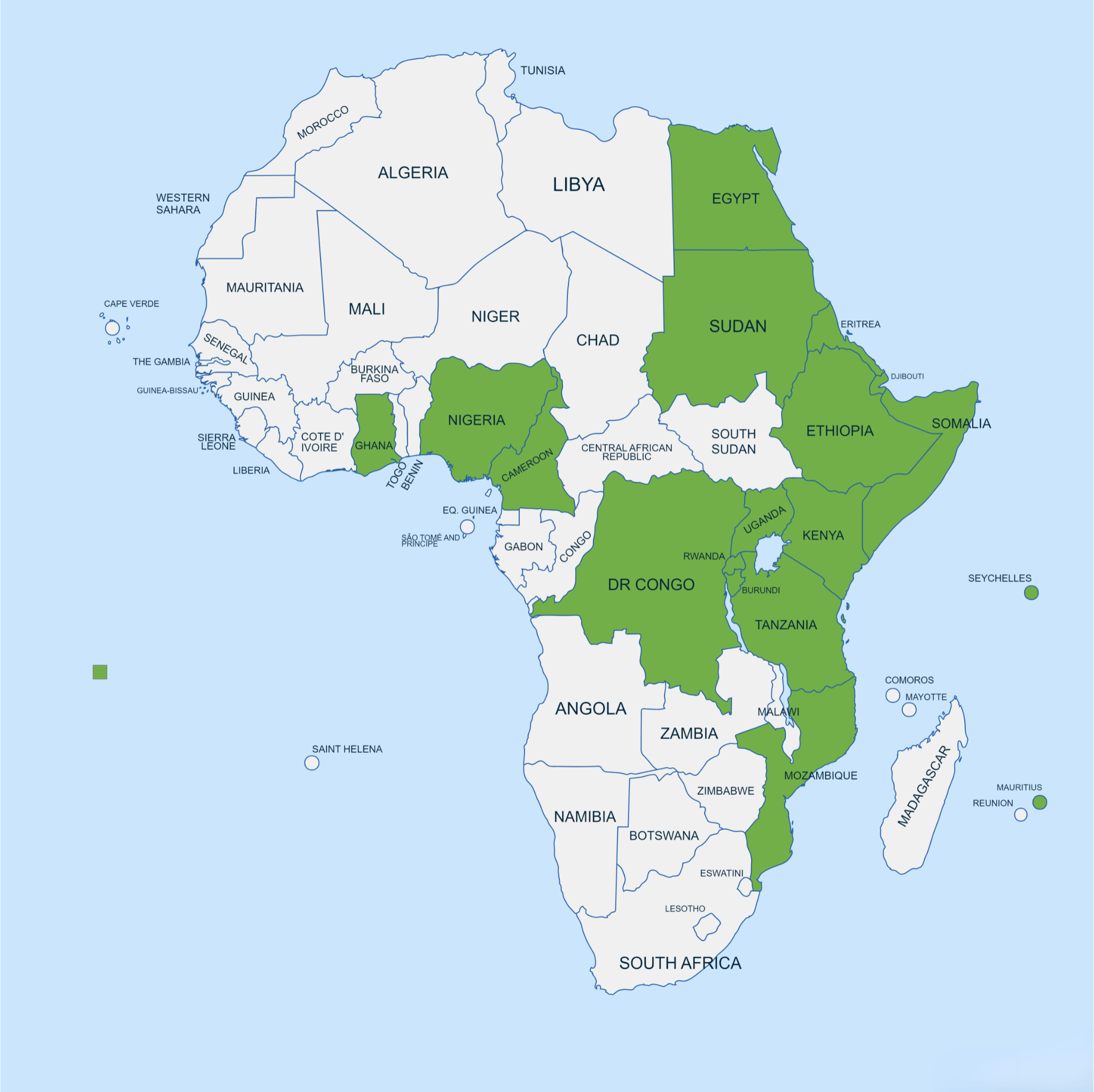

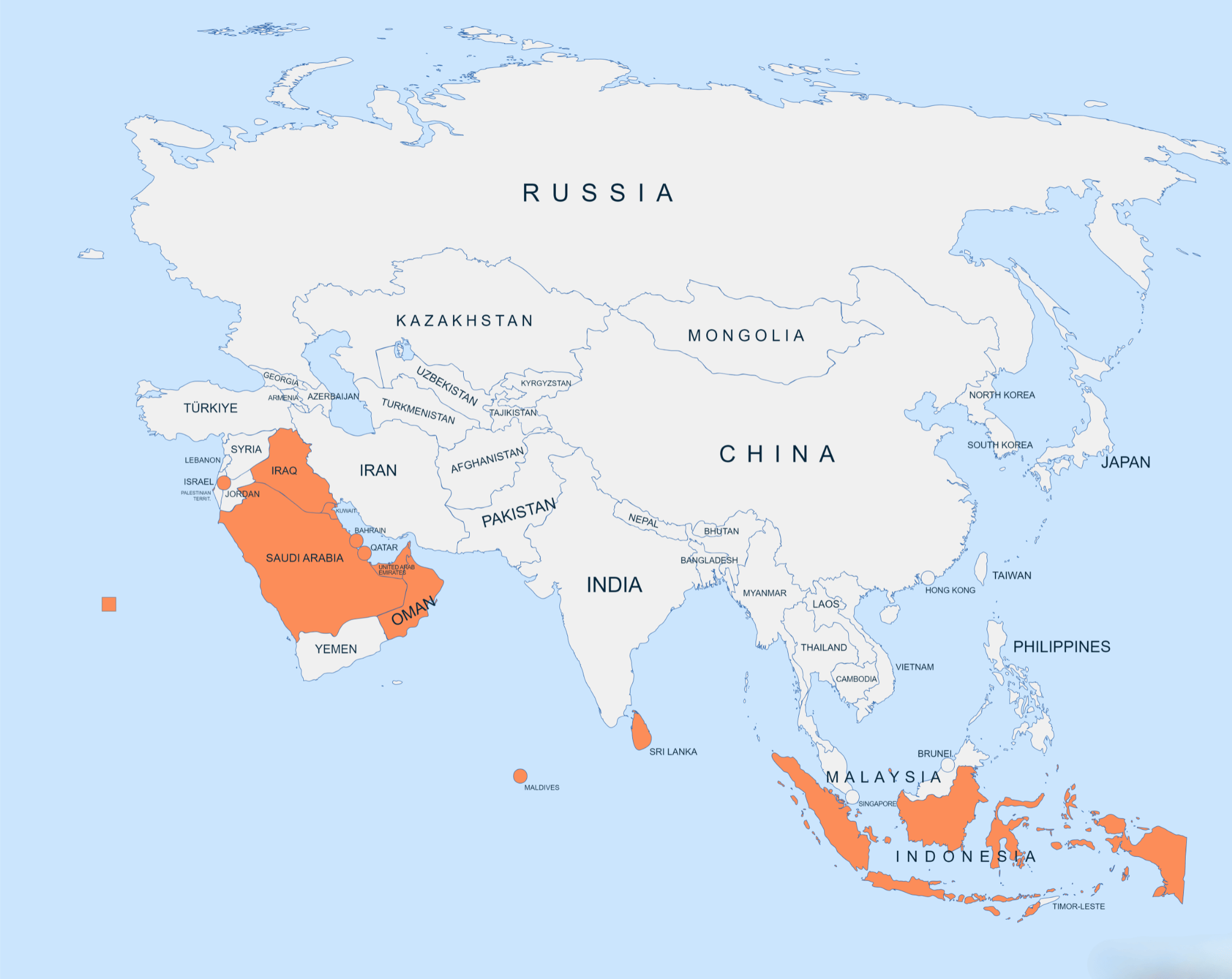

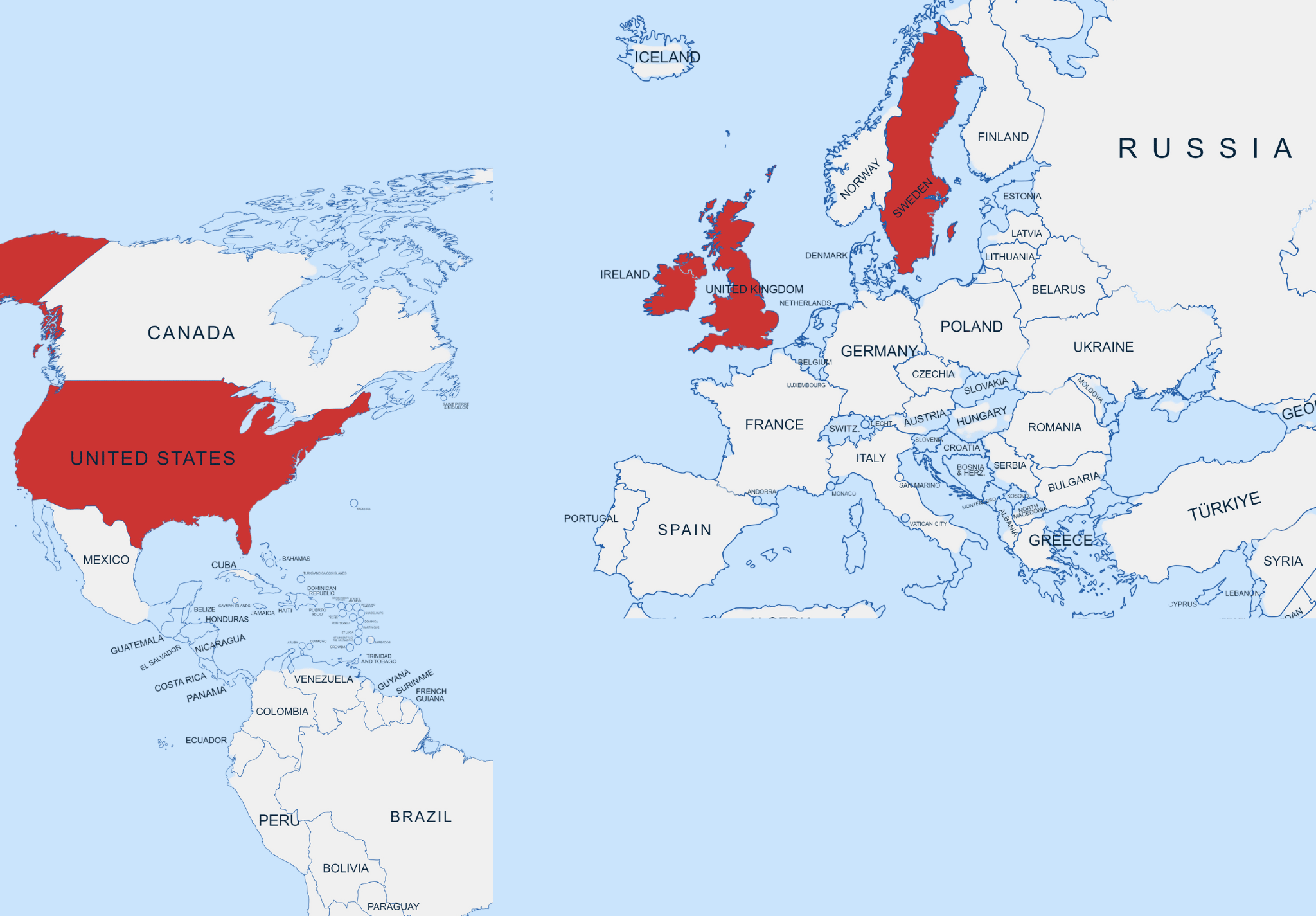

- HDPE Pipes & Fitting in Ethiopia, Kenya, and Ghana

- How Polymer Pipes are Stronger than Metal Ones