Benefits of PVC Pipes

Resistance to Corrosion

Water pipeline deterioration caused by corrosion in old iron pipes threatens our ability to provide safe drinking water and is a complex and costly problem in many parts of the world. PVC pipes are impervious to both underground external corrosion and internal pipe corrosion. So, while some pipe manufacturers continue to look for "solutions" to corrosion because their materials are affected by it, but PVC remains unquestionably resistant to it.

Corrosion in old technology pipes is also the leading cause of burst water mains, when compared to cast iron, ductile iron, concrete, steel, and asbestos cement pipes, PVC pipes has the lowest pipe break rate.

Reduced Wastewater Pipeline Failures and Blockages

Pipe blockages are a major concern in any pipeline system, a costly and complicated problem that can cause untold damage and hours of repairs. Slow moving water through a pipeline increases the possibility of blockages and failures in a system with many connections. When compared to a copper, clay, or concrete pipe, the extremely smooth lining of PVC pipe reduces water flow resistance and ensures that water reaches its intended destination with proper pressure. PVC piping allows water to flow freely while also increasing water pressure. PVC pipe flow increases also prevents build-up in sewage and waste water systems.

Smooth bore allows for high water transfer flow rates

PVC pipes should be considered for water supply pipeline projects because their performance and cost effectiveness outperform alternative materials. Their smooth bore allows for high flow rates, lowering the possibility of blockage and failure. PVC pipes have a proven track record of long-term performance and provide a long, trouble-free service life.

Leak free Joints

The ultra-smooth surface of PVC pipe reduces pumping costs, and its leak-free joints eliminate water loss, which can reach 40% in some old-technology and corrosion-prone piping networks. Elastomeric seals allow PVC pipes to be joined quickly and easily without the use of electricity or weather protection.

Chemical Resistance

PVC pipes are also highly resistant to a wide range of chemical reagents and disinfectant chemicals. As a result, they are an excellent choice for most water infrastructure projects because they can transport the most potent acids, alkalis, aqueous solutions, fluorides, plating solutions, brine, mineral oils, and other chemicals.

long life span

PVC pipes have a proven performance record, and studies from other countries show that PVC pipes have a life expectancy of more than 100 years. A new international water pipe study published in 2014 that included testing on PVC pressure pipes demonstrated the longevity. The combination of pipe examination and testing dates, as well as previous pipe break studies and dig-up reports of in-service pipes, supports PVC's longevity and performance for more than 100 years.

Cost savings

PVC pipes provide significant cost savings for projects, especially when installation, low breakage rates, and life cycle costs are considered. Because PVC pipes last longer, they function more efficiently, reducing maintenance and ongoing work on the pipe and making it more affordable over time. Lower material costs are accompanied by lower installation costs as a result of increased productivity, the product's light weight, and lower transportation expenses.

PVC pipes are not unsafe

PVC pipes are a best option for transporting drinking water. This is due to their high degree of inertness and corrosion resistance. PVC pipes are thus free of bio-film contamination, which can serve as a breeding ground for bacteria. PVC pipes benefit public health by assisting in the transporting the clean water.

Our Other Blogs

- PVC Pipes and their importance

- HDPE Pipes Applications & It's Uses

- Are PVC Pipes Safe for the Environment?

- Benefits of PVC Pipes

- How to Cut and Assemble PVC Pipes Easily?

- How to Perform a Pipe Inspection

- How to Select Plumbing Pipes for a Commercial Building?

- What are the Advantages of HDPE Pipe?

- What are the Different Types of PVC Fittings?

- Why to Use HDPE Pipes and fittings?

- How to Maintain and Take Care of Your Plumbing Systems

- Why Should You Choose Polyethylene Pipe (HDPE pipes) for Your Water Utility Project?

- Points To Consider Before Installing Drainage System

- Everything You Should Know About HDPE Piping for Your Water Utility

- HDPE Piping

- HDPE Pipe Joining Methods

- 5 Reasons to use HDPE pipes in Irrigation System

- Benefits of Using PVC Pipes

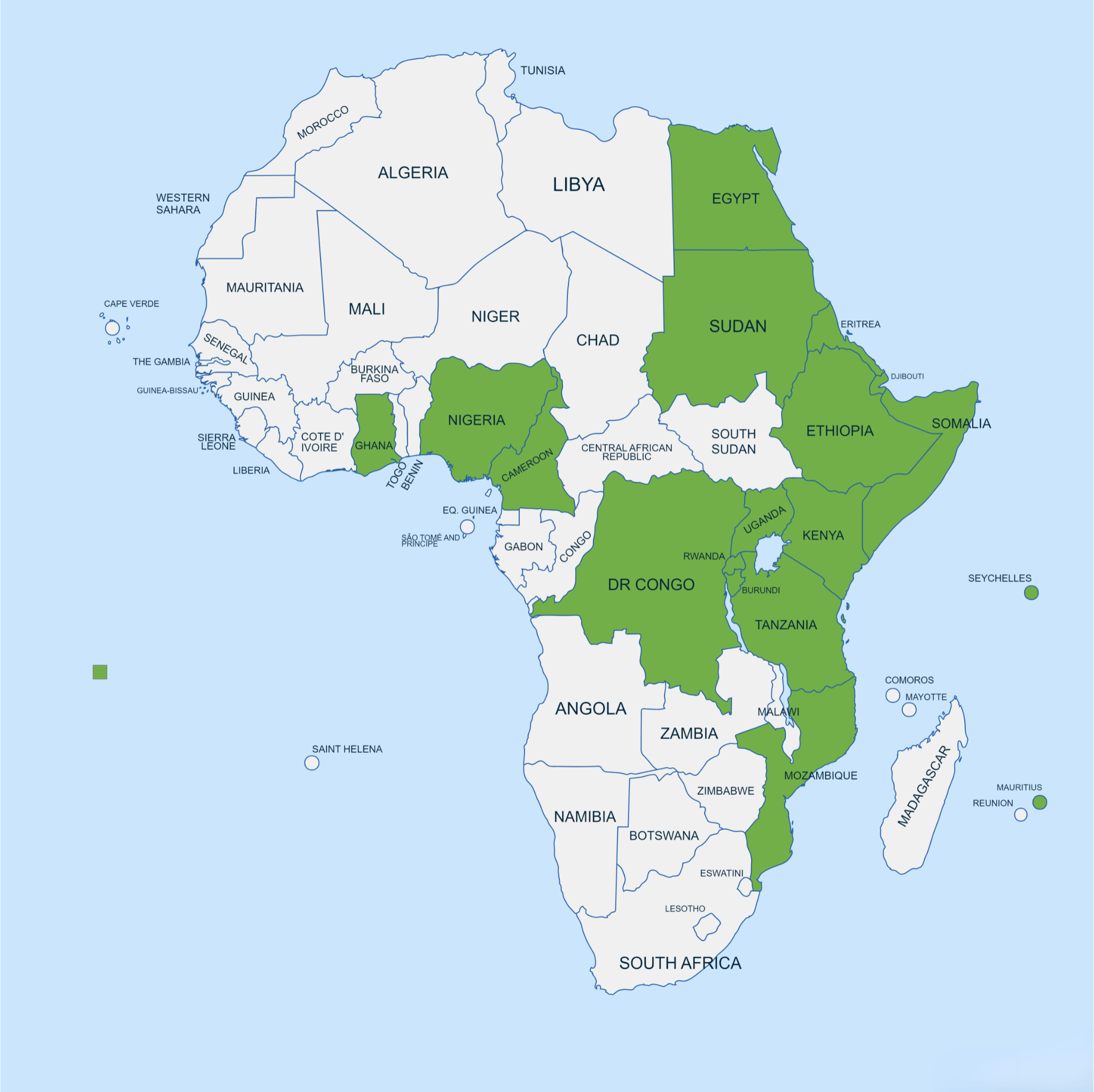

- HDPE Pipes & Fitting in Ethiopia, Kenya, and Ghana

- How Polymer Pipes are Stronger than Metal Ones