HDPE Pipe Joining Methods

There are two methods for joining HDPE pipes. Butt Welding, Electrofusion Welding, or mechanical fasteners are used to connect HDPE Pipe. Pipes made of materials other than polyethylene can be connected using compression fittings, flanges, or other suitable adapters. Connection parts provide convenience based on where they will be used.

There are currently two methods for joining HDPE pipes:

- Electrofusion (EF) welding

- Butt Welding

Electrofusion Welding

Welding is done with heating resistors inside the fusion fitting during the electrofusion welding process. After the pipes are inserted into the Ef fittings, the welding machine's ends are connected to the resistors of the Ef fitting and heated. As a result, the HDPE pipe will be connected to the electrofusion fitting. Pe 100 pipes can be welded using the Electrofusion welding method with HDPE pipes ranging in diameter from 20 mm to 1200 mm. The DVS 2207 standard is followed when performing electrofusion welding.

Butt Welding

Butt welding is the most commonly used welding method for joining HDPE pipes and fittings today. The pipe joining method is a process in which the two ends of the pipes are heated and welded using a butt-welding machine, and then pushed toward each other by pressure at a specific temperature The welding method can be used to join HDPE pipes with diameters up to 1200 mm. The butt-welding method adheres to the DVS 2207 standard.

Comparison of Electrofusion Welding and Butt Welding

- Both welding is executed by licenced welders, and there is no difference in quality between the butt welding and electrofusion welding methods in accordance with DVS 2207 standard.

- To get the best performance out of your work, use the right method in the right place.

- By looking at the welding position, the butt-welding method is superior to the Electrofusion welding method.

- When welding in high ground or where a welding machine cannot fit, electrofusion welding is more advantageous.

- It is more efficient to obtain the welding operation based on the degree of convenience.

- The factors determining weld quality in the electrofusion welding method are greater than those in butt welding (pipe ovality, electrical voltage and continuity, measurement tolerances, etc.). As a result, butt welding is preferable to electrofusion welding.

- Butt welding is less expensive than electrofusion welding in terms of welding costs.

- In terms of the after-welding procedure, electrofusion welding is more advantageous.

Summary

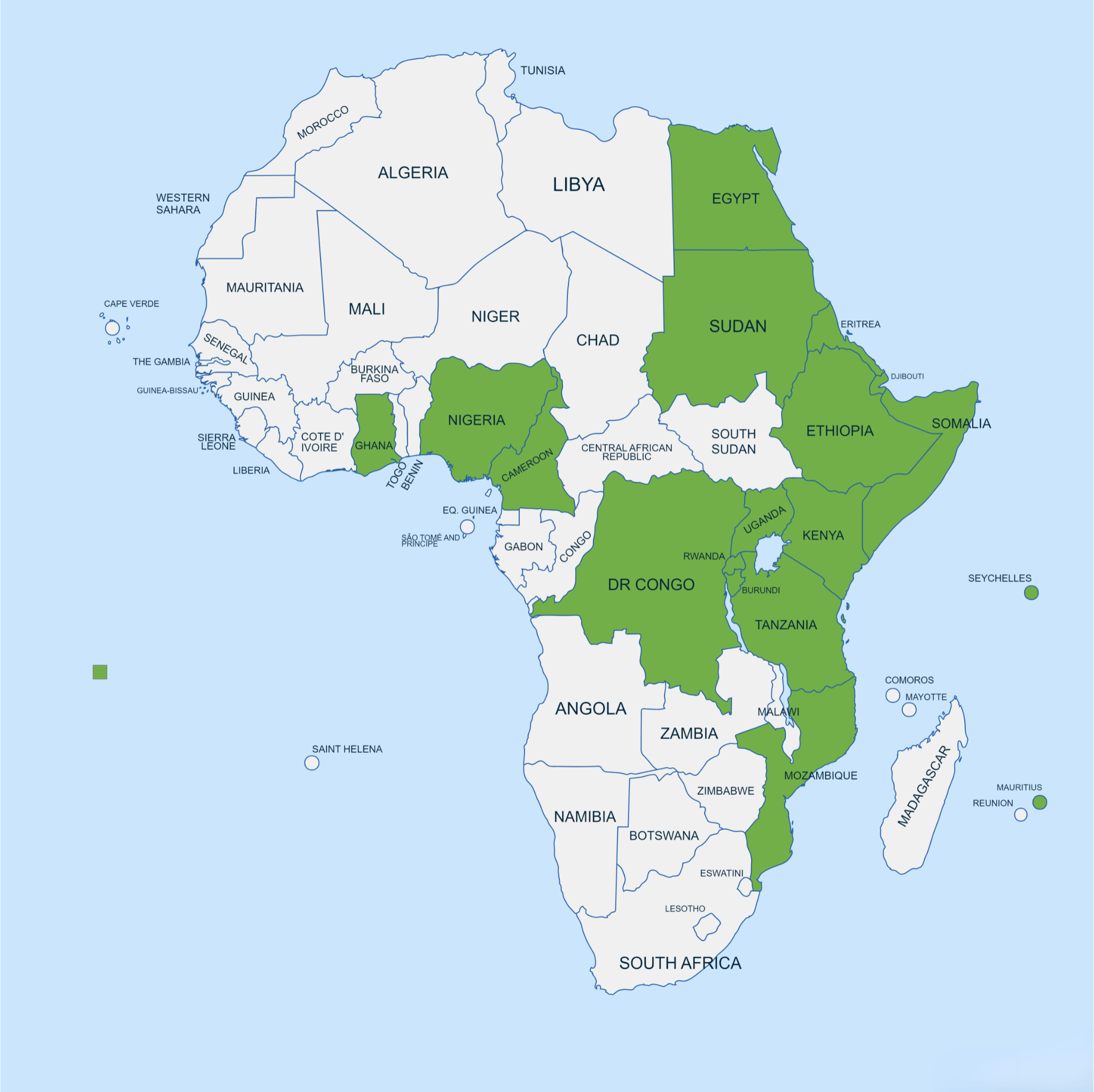

HDPE pipes can be connected using the above explained method. Polyfab provides the best HDPE pipes and welding machine in Ethiopia, Kenya and Ghana. Contact our sales team to know more about the HDPE pipes and welding machine.

Our Other Blogs

- PVC Pipes and their importance

- HDPE Pipes Applications & It's Uses

- Are PVC Pipes Safe for the Environment?

- Benefits of PVC Pipes

- How to Cut and Assemble PVC Pipes Easily?

- How to Perform a Pipe Inspection

- How to Select Plumbing Pipes for a Commercial Building?

- What are the Advantages of HDPE Pipe?

- What are the Different Types of PVC Fittings?

- Why to Use HDPE Pipes and fittings?

- How to Maintain and Take Care of Your Plumbing Systems

- Why Should You Choose Polyethylene Pipe (HDPE pipes) for Your Water Utility Project?

- Points To Consider Before Installing Drainage System

- Everything You Should Know About HDPE Piping for Your Water Utility

- HDPE Piping

- HDPE Pipe Joining Methods

- 5 Reasons to use HDPE pipes in Irrigation System

- Benefits of Using PVC Pipes

- HDPE Pipes & Fitting in Ethiopia, Kenya, and Ghana

- How Polymer Pipes are Stronger than Metal Ones