Everything You Should Know About HDPE Piping for Your Water Utility

There are numerous possibilities when it comes to installing pipes lines for your water utility, but which one would be most effective? We discovered that not all of our customers were as aware with this recent information as we were. We put up this fast guide to assist you determine if it's a good fit for your needs because we kept getting a lot of questions about what it can and can't do, how to install it, and whether it really is the best option for your water utility.

Leakproof

HDPE pipes are thermally fused together, making them leak-proof because couplings are their only possible point of failure. According to studies, all HDPE pipes that burst do so in the main portion of the pipe, no breaches occur at the fused connections.

Resistant to chemicals and erosion

Since HDPE is a form of plastic, it doesn't corrode and is incredibly resilient to harsh environmental conditions. When your pipes aren't capable of leaching lead, issues like the Flint water crisis can't occur.

Flexible and resistant to fatigue

We've all seen trenches that weren't as straight as they should be. These trenches were flexible and fatigue-resistant. Due to its flexibility, HDPE is a considerably more tolerant material in that circumstance. It also withstands wear and tear, so routine movement won't lead to a weak spot.

Lightweight but powerful

Want to install quickly without worrying about impact damage? For this application, HDPE is an excellent pipe material. Despite its light weight, it is far tougher and more impact resistant than other similar plastic piping options.

HDPE Installation, Maintenance, and Repair

Working on HDPE pipe allows you to have the best of both worlds. It's joined using thermal fusion, which creates a tight seal while remaining lightweight and manoeuvrable. In contrast to metal pipes, which can corrode, leak, and leach metals into the water being transported, HDPE is resistant to most soil and water conditions. This means fewer maintenance tasks and trips for your crew, as well as more money in the bank. It works well in conditions where ductile iron, PVC, and cement pipe are ineffective. Because of its versatility, HDPE can be used for horizontal drilling, slip lining, plough and plant, floating or submerged pipe without causing significant problems.

HDPE Price Comparison

HDPE is a low-cost, long-term solution for your water utility's pipe needs. The Plastic Pipe Institute estimates its current expected lifespan to be between 50 and 100 years.

Summary

We hope that this guide has helped to answer some of your questions about HDPE pipe, which is a versatile material that meets many of the demands placed on it by water utilities across the country. If you have any questions or would like a quote for your upcoming water utility needs, please contact Polyfab team today for more information.

Our Other Blogs

- PVC Pipes and their importance

- HDPE Pipes Applications & It's Uses

- Are PVC Pipes Safe for the Environment?

- Benefits of PVC Pipes

- How to Cut and Assemble PVC Pipes Easily?

- How to Perform a Pipe Inspection

- How to Select Plumbing Pipes for a Commercial Building?

- What are the Advantages of HDPE Pipe?

- What are the Different Types of PVC Fittings?

- Why to Use HDPE Pipes and fittings?

- How to Maintain and Take Care of Your Plumbing Systems

- Why Should You Choose Polyethylene Pipe (HDPE pipes) for Your Water Utility Project?

- Points To Consider Before Installing Drainage System

- Everything You Should Know About HDPE Piping for Your Water Utility

- HDPE Piping

- HDPE Pipe Joining Methods

- 5 Reasons to use HDPE pipes in Irrigation System

- Benefits of Using PVC Pipes

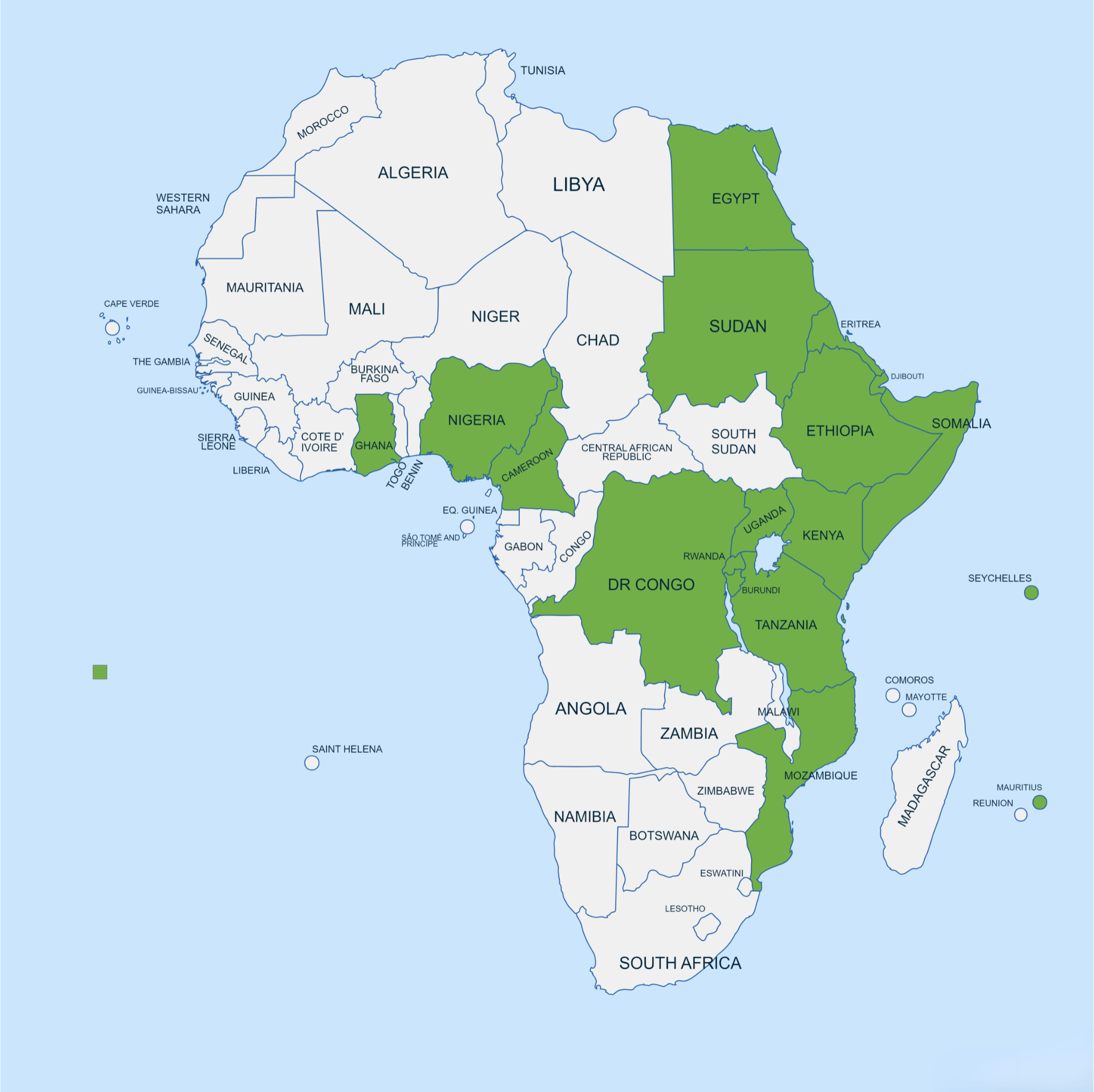

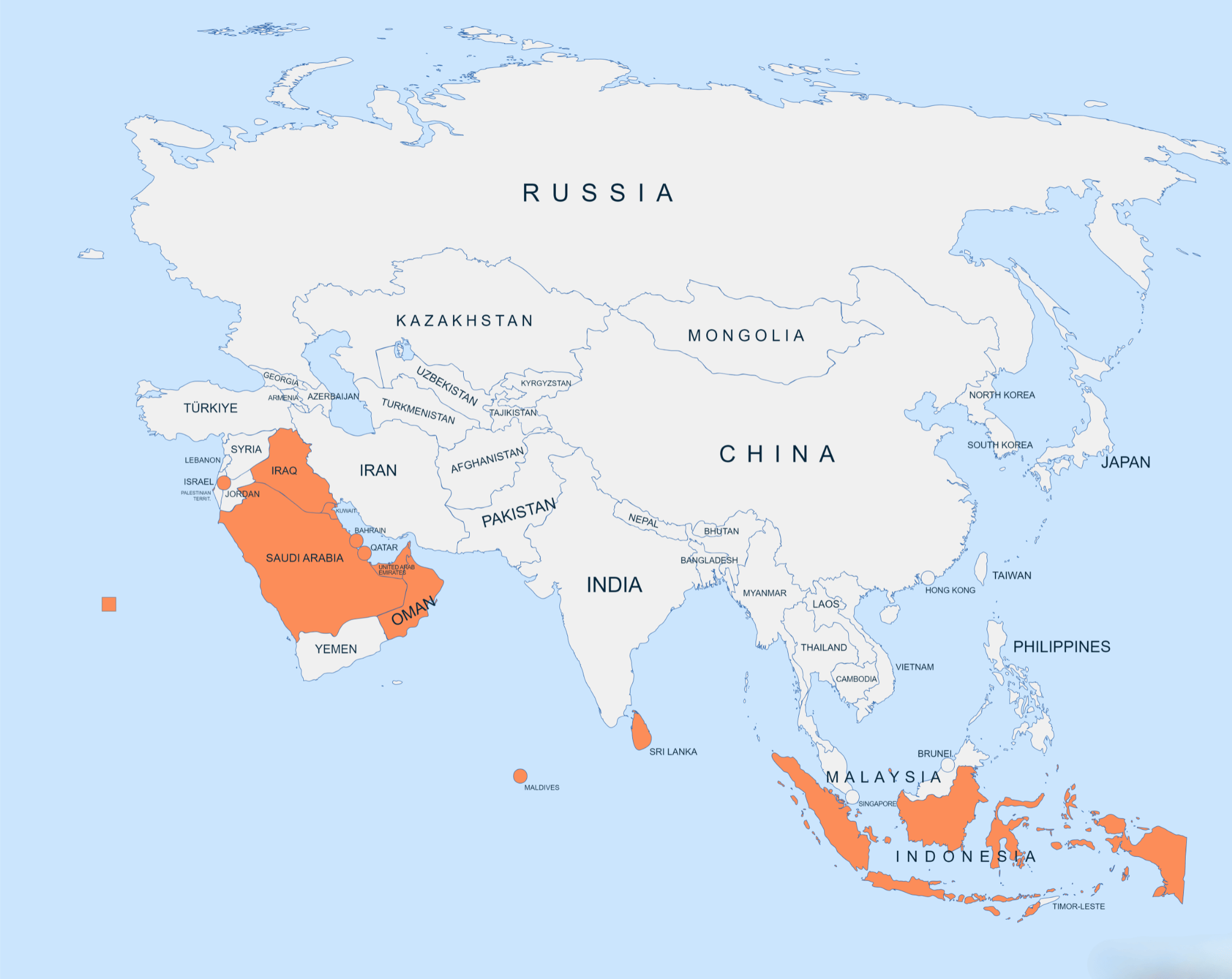

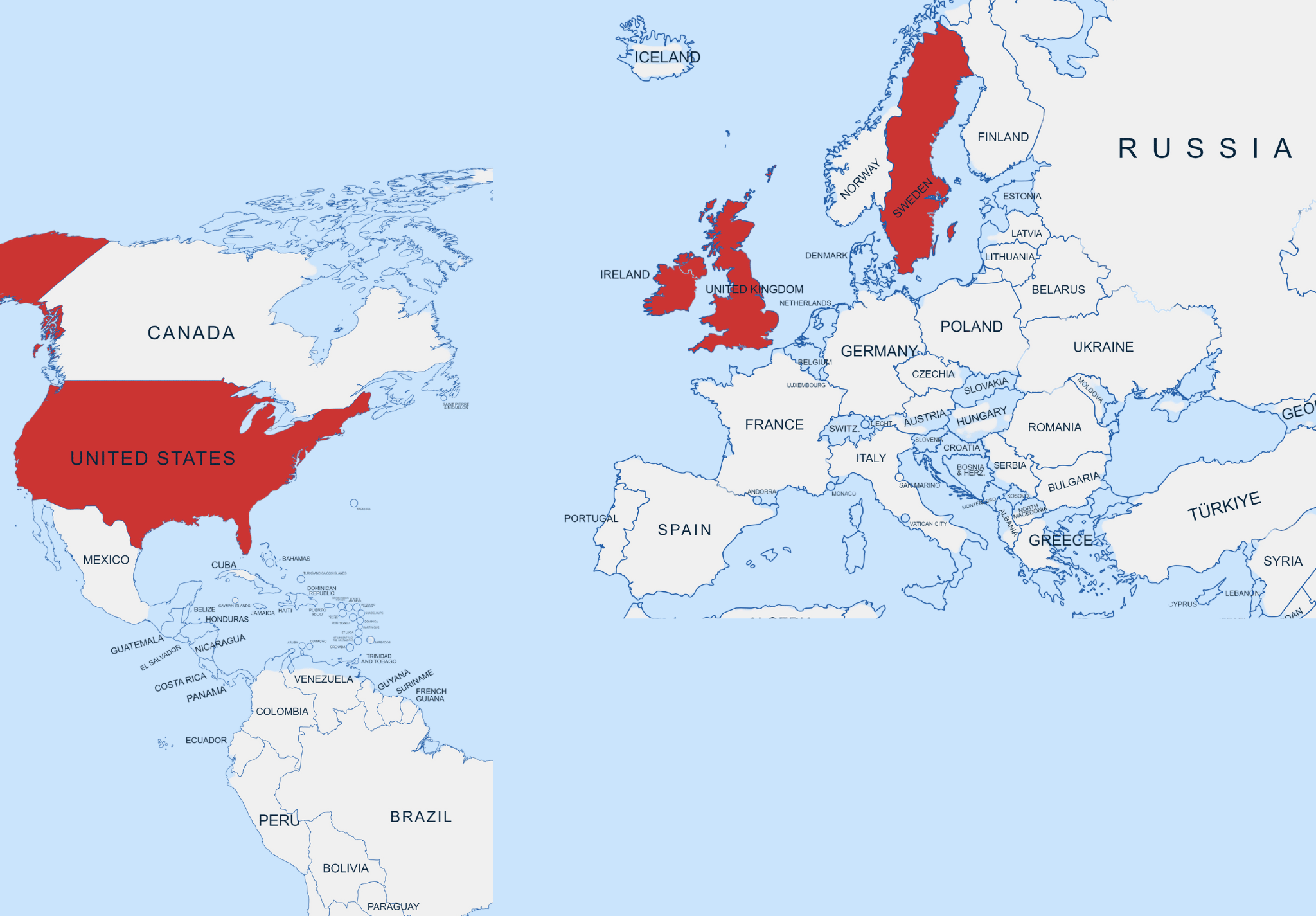

- HDPE Pipes & Fitting in Ethiopia, Kenya, and Ghana

- How Polymer Pipes are Stronger than Metal Ones